hardness test of rubber|rubber hardness chart : trade The most commonly used gauges for measuring the hardness of rubber are the durometer and the IRHD meter. The hardness of rubber measured by means of a durometer is expressed in the unit Shore A. A . Resultado da Hi there! If you're new to this wiki (or fandom) and plan on making an account, please check out our Rules page, for information on new accounts and some rules to follow.

{plog:ftitle_list}

Isadora vale (@isadoravaleofc) no TikTok |275 curtidas.1.2K seguidores.🌟 Bem-vindo(a) ao meu mundo! O que vc procura tá👇.Assista ao último vídeo de Isadora vale (@isadoravaleofc).

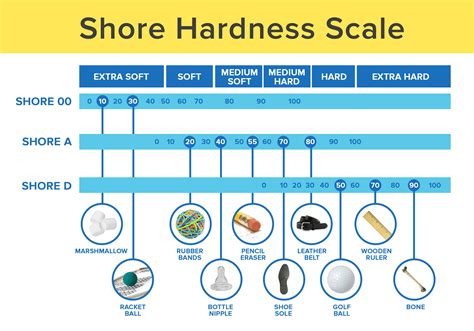

shore rubber hardness scale

Hardness value is determined by the penetration of the Durometer indenter foot into the sample being tested. The resilience of .The procedure for determining indentation hardness of substances classified as thermoplastic elastomers, vulcanized (thermoset) rubber, elas-tomeric materials, cellular materials, gel-like .

satuan hardness rubber

The most commonly used gauges for measuring the hardness of rubber are the durometer and the IRHD meter. The hardness of rubber measured by means of a durometer is expressed in the unit Shore A. A .

The procedure for determining indentation hardness of substances classified as thermoplastic elastomers, vulcanized (thermoset) rubber, elastomeric materials, cellular .

The Shore hardness value indicates the degree of indentation resistance of a material when a specific force is applied. It is a vital parameter for rubber manufacturers, as it helps determine the material’s suitability for .

Test the hardness of thin and irregularly shaped plastic, rubber, and laminate parts, such as O-rings. These testers can be used on products where the surface area is too small for accurate durometer readings with a standard Shore A tester, such as the rounded surface of O-rings. They include O-ring fixtures that hold five standard-sized O-rings in place during testing.

Name: Hardness Instrument/Equipment: Durometer Test Type: Physical Testing Material: Cured Rubber Standards: ASTM D2240. Specific Gravity. . In a flex fatigue test, a rubber sample is subjected to repetitive cyclical bending at low stresses for set number of cycles. Often, this is performed at an elevated temperature to further accelerate the .Rubber hardness testing is one of a wide range of materials testing services available from Inspiratech 2000 Ltd. MATERIALS.CO.UK . Standard Test Method for Rubber Property-International Hardness: ASTM D2240-15e1: .

The Shore D hardness scale is a test method that determines the hardness of a material. Learn more about it here. . The Shore D Hardness Scale is a method and reference system for measuring the hardness of materials such as rubber and plastic with a tool called a durometer. The exact measurement points to how much force a material can handle .

rubber hardness testing methods

Scope1.1 This test method describes eight types of rubber hardness measurement devices known as durometers: types A, B, C, D, DO, O, OO and M. The procedure for .The Shore Duromter A and D scales of hardness are commonly used for rubber and 'soft' polymers such as polyolefins, polyurethanes, vinyl, and fluoropolymers. . so the indentation time is sometimes reported along with the hardness number. The ASTM test method designation is ASTM D2240 00 and is generally used in North America. Related methods .Get all the information you need on hardness testing and hardness test methods from ZwickRoell! Definition Examples Products for hardness testing More information. . The following methods are used for hardness tests on rubber-elastic polymers and elastomers: Shore: ISO 7619-1: ASTM D2240: Ball indentation hardness: ISO 2039-1: Rockwell: ISO .What is Mohs Hardness Scale? The Mohs Hardness Scale is a set of ten reference minerals (numbered 1 through 10) that are used to determine the relative hardness of minerals and other objects. In this test the hardness of a mineral is defined as its "resistance to being scratched". A list of the Mohs Hardness Scale Minerals is shown in the table below.

Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The loads required are listed in Table 1 below: Table 1: Different Hardness Test Methods and Their Corresponding Loads. Method Load Range Standard; Method. Brinell. Load Range. 1 kgf–3,000 kgf. Standard. ASTM E10, ISO 6506. Method. The Shore A hardness scale is widely used in the polymer and plastics industry to characterize the hardness of various materials. Manufacturers use durometer testing as a quality check for manufactured products. For example, silicone hardness or rubber hardness can easily be measured and evaluated against manufacturing standards.ZwickRoell offers a comprehensive portfolio of hardness testers for tests on metals, ceramics, plastics, rubber and special materials. These instruments meet the requirements of all relevant hardness test methods and internationally accepted standards. With our ISO/IEC 17025 UKAS and DAkkS accredited calibration laboratories, ZwickRoell guarantees precise and certified .

Test Type: Natural Rubber. . Hardness: Durometer: Cured Rubber: ASTM D2240: Specific Gravity: Specific Gravity Balance: Cured Rubber: ASTM D792: Dispersion: Dispergrader: Uncured/Cured Rubber: ISO 11345, ASTM D7723-19: Hardness. The hardness of a material is measured by using a relatively harder material to deform the surface using a small .

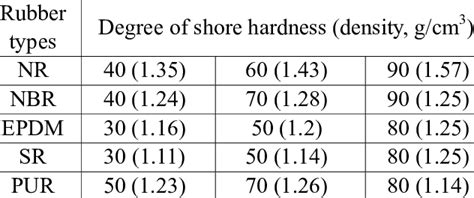

Generally, most rubber materials fall under the rubber durometer scale of Shore A. Thus, if you need a rubber or O-ring durometer that feels like a running shoe sole, review our rubber hardness chart below, then pick Shore 70A. A rubber durometer of Shore 70A is the most commonly chosen material hardness for all applications. a. Shore 20A .

Shore Hardness Test: Specifically designed for elastomers and plastics, this test measures the material’s resistance to indentation using a standardized indenter. It’s crucial for assessing materials like rubber or silicone. Mohs Hardness Test: This qualitative test ranks minerals based on their scratch resistance against standard materials .standard hardness S hardness, in international rubber hardness degrees, obtained using the procedures described in ISO48-2 on test pieces of the standard thickness and not less than the minimum lateral dimensions specified 3.3 apparent hardness hardness, in international rubber hardness degrees, obtained using the procedures described inThe indentation hardness is then determined based on the elastic modulus and viscoelastic behavior of the sample. Test Details The ASTM D2240 test method is used to evaluate the hardness of the following types of rubber materials: .RUBBER HARDNESS. Elastomeric materials are usually measured with either a Shore A Scale Durometer or an IRHD dead load system. These tests are designed for use with samples approx 6mm thick, and a surface area sufficient .

The IRHD test is a non-destructive form of rubber quality test and is the most preferred method for final product inspection in the rubber industry. The International Rubber Hardness Degrees (IRHD) scale has a range of 0 to 100, corresponding to the elastic modulus of 0 (0) and infinite (100), respectively.ISO 7619-1:2010 specifies a method for determining the indentation hardness (Shore hardness) of vulcanized or thermoplastic rubber by means of durometers using the A scale for rubbers in the normal-hardness range; the D scale for rubbers in the high-hardness range; the AO scale for rubbers in the low-hardness range and for cellular rubbers; and the AM scale for thin rubber .

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .This is because 40-70 durometer hardness ratings indicate a mid-range rubber hardness. Rubber materials in this range generally very durable and resilient, with excellent physical resistances. 60 durometer rubber in particular is a favorable choice because it can hold up against heavy impacts and abrasions without sacrificing its sturdy form.The rubber durometer chart is a scale of measuring the hardness of a rubber material, developed by Albert Shore in the 1920s. The durometer hardness specifically measures an elastomer’s resistance to indentation. Need Help Call 1-844-Rubber-4. Cart . Total Item(s): () Checkout. Sheet Rubber. Industrial Rubber.The Vickers hardness test is another method used to measure the hardness of materials. It uses a diamond pyramid indenter to create an indentation on the material’s surface under a specified load. . Durometer testing is commonly employed to measure the hardness of rubber and plastic materials, and the results guide material selection based .

measuring coating thickness on concrete

Brinell hardness test is an indentation hardness test. It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the material for a set amount of time (between 10 – 30 seconds, known as the dwell time). . Scale A: Ebonite rubber 100 .

The rubber shore hardness test is a fundamental evaluation method used to measure the hardness of rubber materials. Shore hardness is a measure of the resistance a material has to indentation. This test is crucial for determining the suitability of rubber for various applications, ensuring that it meets the required standards for performance .The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the .

In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation, such as an indentation (over an area) or a scratch (linear), induced mechanically either by pressing or abrasion.In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as .

rubber hardness measurement unit

rubber hardness chart

rubber durometer hardness

Comando 190. JI-PARANÁ - POLICIAL. Acidente entre Camionete e Motocicleta deixa Jovem ferido em Ji-Paraná. JI-PARANÁ - POLICIAL. Homem é preso após agredir mãe .

hardness test of rubber|rubber hardness chart